MACHINING

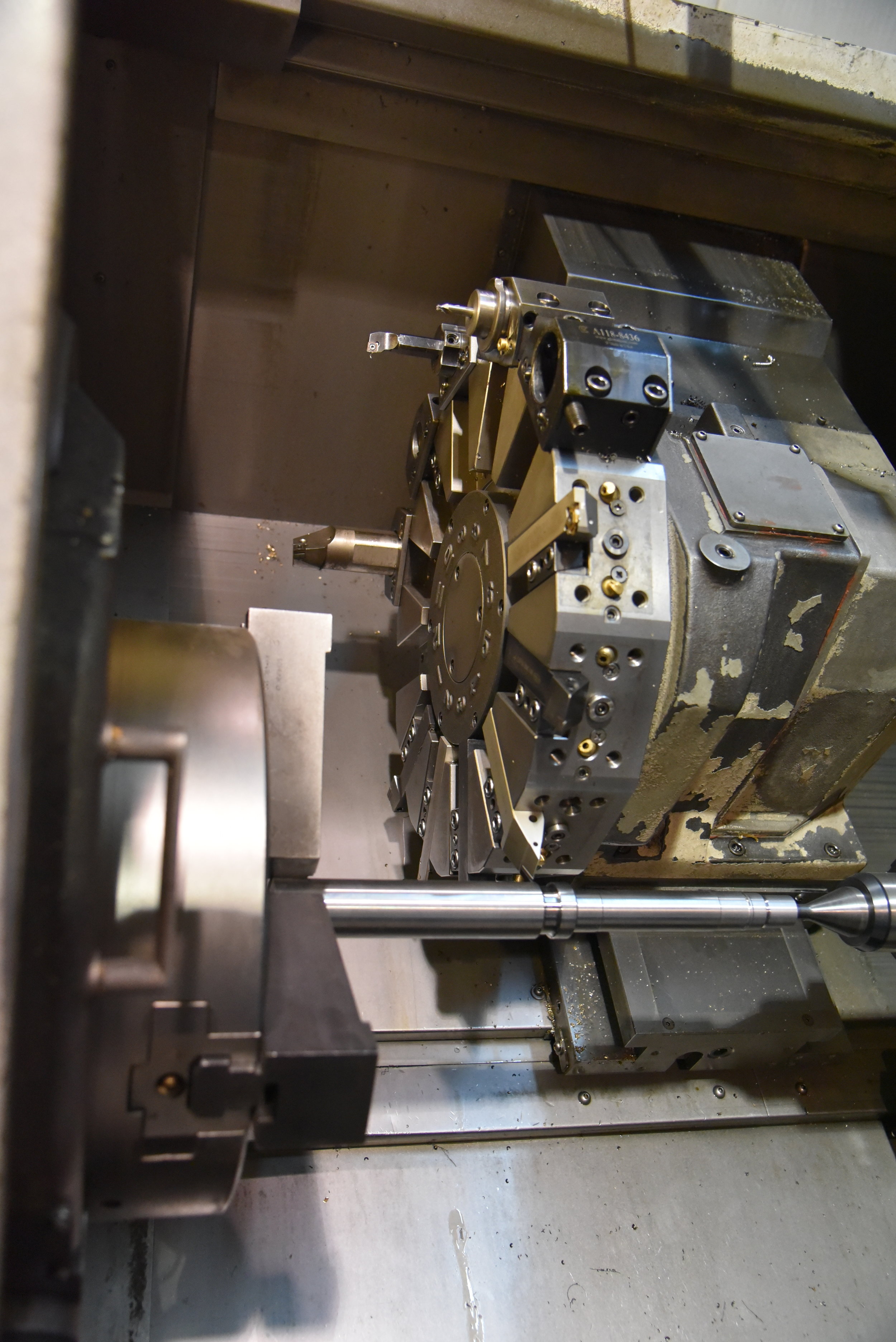

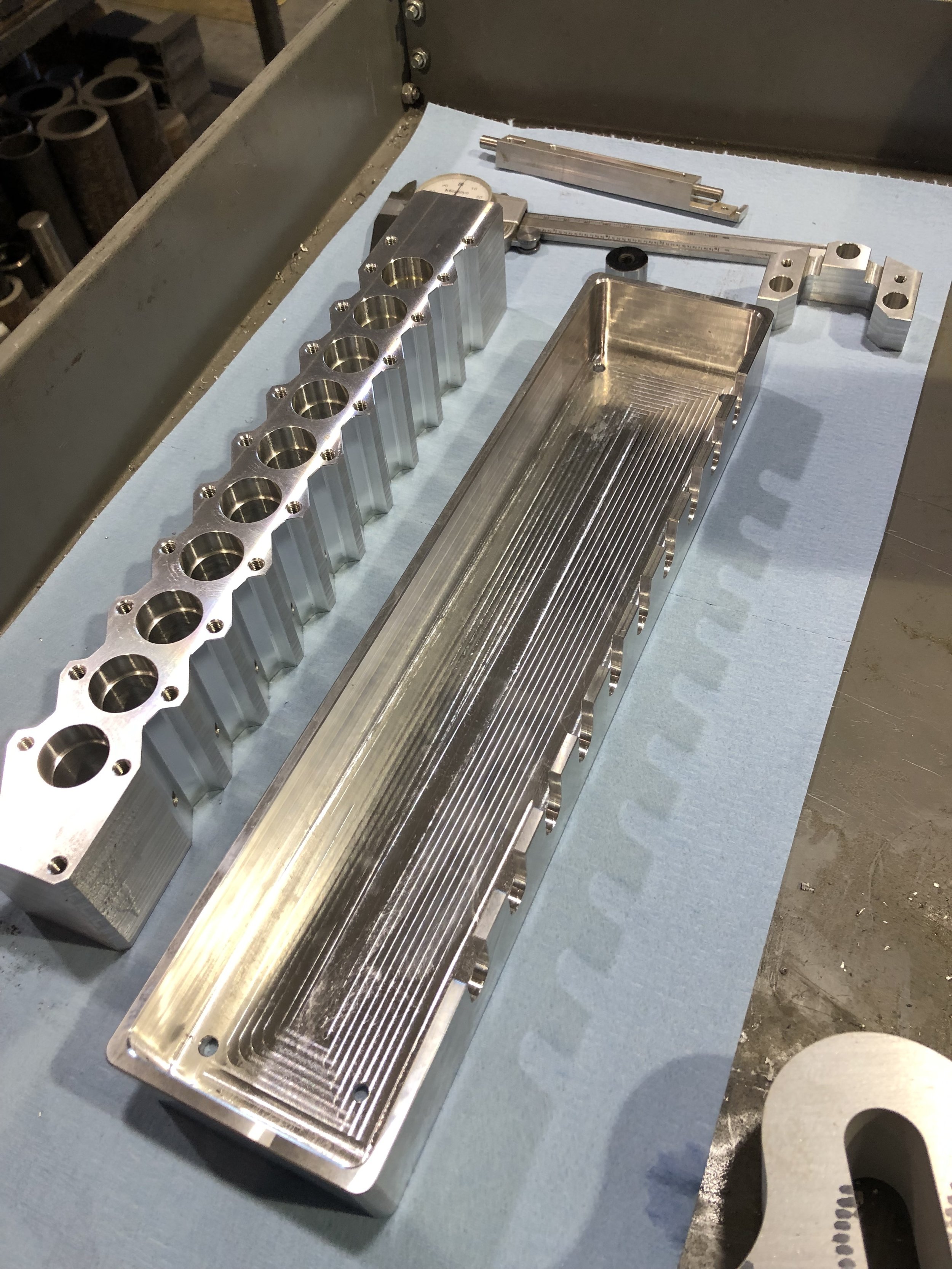

We offer both CNC and conventional machining including turning and milling. We are capable of holding tight tolerances using state-of-the-art machining and measuring equipment to ensure the highest quality product and customer satisfaction.

Our 5-axis milling capabilities offer minimized set-up, complex designs, rotational accuracy, faster material removal and better surface finishes ensuring efficiency in both material use and hours, allowing us to provide our customers with the most cost effective service.

Milling

Precision greater than +/- .0005 inches

Part Sizes up to 48 x 20 x 20 inches

Turning

Precision greater than +/- .0005 inches

Part Diameter up to 24 inches

Part Length up to 40 inches

Victaulic pipe grooving (machined or roll groove)

NPT Pipe Threading

CNC Shear - 10’ x 1/2” capacity

Horizontal Band Saw - 20” x 13” with up to 30 deg mitre